Herbarom Laboratoire, inspired by nature, guided by what's essential.

We provide a tailor-made response to the innovations of our industrial customers, transforming each plant extract into a differentiating source of success.

Exceptional raw materials, trusted partners and uncompromising traceability.

Nutrition & human health

HERBAROM Laboratoireyour ally

for high-performance natural solutions

Essential oil

Plant water

Hydrolate

Vegetable oil

Macerated oil

Butter

Aromatic substances

Plant powders

Specialist in natural ingredients and the development of standardised or customised plant extracts. Herbarom Laboratoire supports manufacturers in the animal nutrition, health, cosmetics and food sectors.

With over 30 years' expertise in plant extraction. Herbarom Laboratoire develops tailor-made solutions, using rigorously selected raw materials, to meet the challenges of effectiveness, naturalness and traceability.

From botanical selection to the manufacture of active ingredients, via R&D development, Herbarom offers a global approach that is at once technical, regulatory and sustainable, to enhance the value of plants in the service of product innovation.

One group, two areas of expertise

Food Supplements

Expert in the development and manufacture of tailor-made food supplements

- The phytotherapy and the use of functional active ingredients at the heart of our solutions

- Mastery of flavouring

- Knowledge of regulations in force on this market

Ingredients

Specialists in the production, sourcing and tailor-made development of plant extracts

- Mastering sourcing and setting up sectors

- Cultivate, Control, Secure sourcing your ingredients

- Enhance the best that nature has to offer

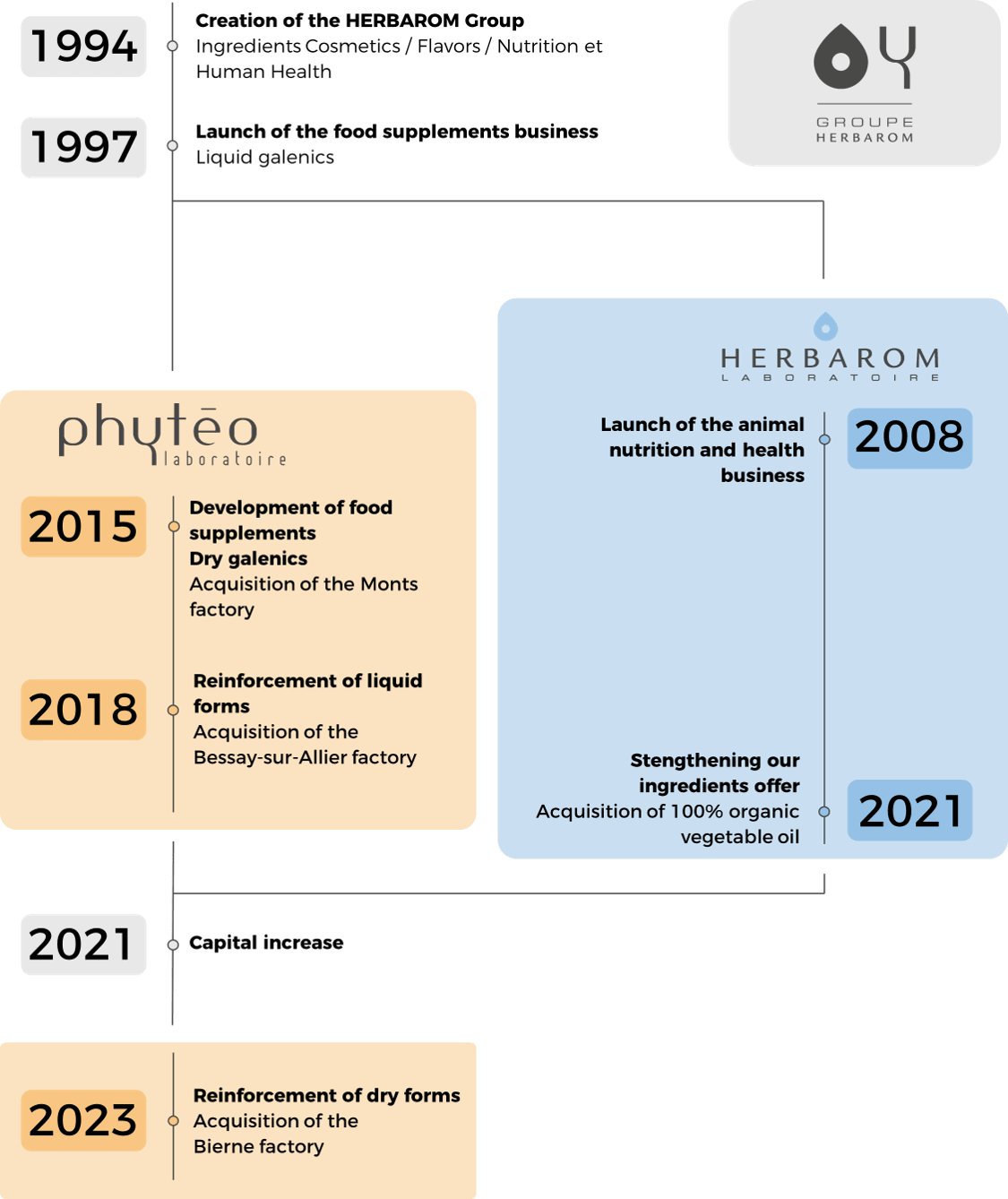

30 years of expertise

The creation of Herbarom

Launch of the food supplements business

Launch of the food and animal health business

Development of dry galenic food supplements

Reinforcing liquid forms

Boosting the range of ingestibles

Opening of capital

Dry form reinforcement

Some products

Made in France and organic

It is with great pride that our natural solutions have continued to be produced in France for over 30 years, at four production sites:

- Aouste-sur-Sye, in the Drôme department: specialised in plant extraction

- Bessay-sur-Allier (03) : specialised in liquid galenic forms

- Bierne (North of France) : specialised in dry galenic forms and pharmaceutical products

- Monts (37) : specialised in dry galenic forms

- Valence (26) Group headquarters, where management and support functions are based.

Many of our plant-based ingredients are available in organic versions. We are committed to promoting organic farming with our agricultural partners in the Perfume, Aromatic and Medicinal Plants sector, with our roots in Drôme – a pioneering region in organic farming.

At HERBAROMOur aim is to take care of what nature has to offer, while meeting the needs of our customers. To achieve this, we have chosen to use ancestral plant extraction methods that we have adapted to an industrial scale.

Methods extraction methods : distillation, extraction, mechanical pressure

Each year, we process more than 900 tonnes of raw material,whether dry or fresh, in our production units, to make our natural ingredients.

From these plants, we extract our ingredients through three main techniques: distillation, extraction and mechanical pressure.

Steam distillation: the various steps

Steam distillation makes it possible to obtain essential oils, hydrolates and plant waters, which include distilled waters and floral waters.

Distillation is a demanding and delicate technique. Here, we must extract the most subtle but also most fragile aromatic substances from the plant, aiming to never alter its qualities.

Four main steps are required to distil a plant :

- The steam passes through the plant to extract the volatile elements contained in the plant's essence pockets.

- Upon contact with heat, these pockets explode and release their precious contents. The molecules and olfactory notes of the plant are then released.

- The steam, then laden with essential oil, circulates in a coil surrounded by cold water and returns to liquid form through condensation.

- The precious liquid flows to the Florentine flask, where the distillate is collected.

The plant therefore releases its volatile molecules, guided by the hand of man and in total respect for nature.

This steam-distillation process can be applied to a very wide variety of plants. This historic industrial technique requires all our know-how, and forms part of our values of environmental protection and respect for the plant and its very essence.

Extraction based on oil, water or alcohol

Extraction makes it possible to obtain macerated oils, aqueous extracts, hydro-alcoholic extracts, hydroglycerine extracts and even glycolic extracts.

Plant extraction is a process which aims to extract certain components from plants. This operation separates solids from liquids. In other words, the plant, the solid body, is immersed in a solvent which may be oil, water, alcohol or a mixture of several solvents. The desired plant compounds are then solubilised and captured in the solvent. As a result, we obtain the desired extract.

Extraction by brings together two major processes:

- Maceration: static process at room temperature or hot with slow infusion

- Leaching: dynamic process with the continuous circulation of a fluid to deplete the plant

Then, at the end of the extraction operation, the plant and solvent are separated by decantation or pressing.

The extract obtained is then filtered. Filtration can range from simple clarification of the extract to so-called sterilising filtration, depending on particular needs.

The extract can also be pasteurised to eliminate microorganisms and the risk of bacterial contamination.

It is also possible to concentrate the extracts by removing a portion of the solvent.

Mechanical pressing

Mechanical pressing makes it possible to obtain vegetable oils and butters, as well as certain essential oils, in particular those of citrus fruits.

This includes cold-pressing, hot-pressing and hydraulic-pressing processes, among others.

These extraction operations are complex and sensitive. They require both the total mastery of plant properties and extraction techniques. However, the mastery of mixtures, dilutions, plant/solvent ratios, temperatures, extraction times and rest times are all know-how that we have acquired over the last 25 years.

Did you know? We work with over 150 different plant species to make our natural ingredients. Available in different forms, we will accompany you to find and define that most suited to your use.

Ingredients

natural and organic

As a specialist in natural ingredients, our ranges are largely made up of certified organic ingredients.

Furthermore, our three production sites have been certified for organic farming.

As a guarantee of quality and traceability, this certification offers yet another way for you to stand out from your competitors and market products that meet your customers' expectations in terms of naturalness.

Responsible manufacturing

and certified to secure your project

Our production sites in France apply good manufacturing practices and the HACCP approach to guarantee hygiene, traceability and quality. Committed to a socially and environmentally responsible approach, we develop certified and responsible solutions tailored to the requirements of your market.